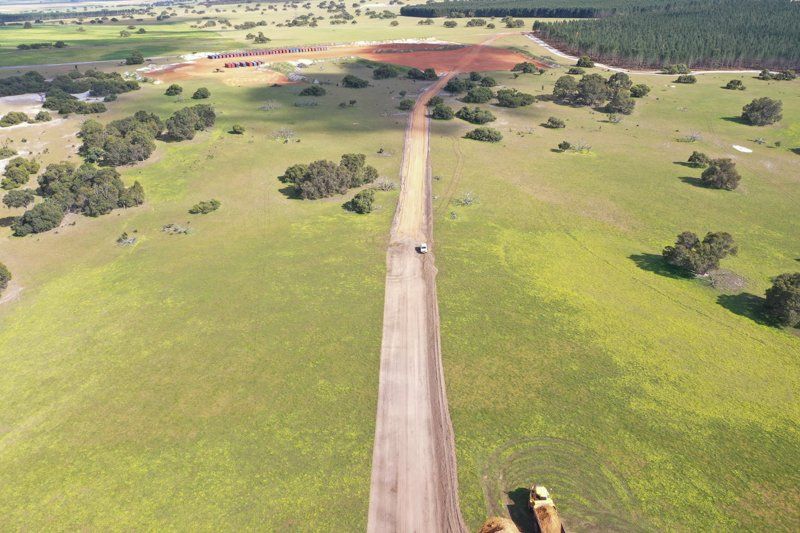

Vernice are currently working on upgrades to Carrabin’s main roads

Client: Decmil Australia

Project: Owners: Vestas

Owners: Alinta Energy

Date: August 2019 – December 2020

The Yandin Wind Farm – 175km north of Perth, near Dandaragan – comprises 51 turbines, each with a capacity of 4.2MW.

The joint venture between Ratch Australia and Alinta Energy was shaped by valued input from local community and landowners, and is expected to cost $400 million. Alinta Energy is managing the investment.

The connection to the Western Power network, through a 330kV terminal and 10km transmission line, was revealed by Decmil, who won the $79 million civil, electrical design, and construction contract. With electrification complete, the wind farm delivered its first output to the state’s grid, the South West Integrated System, on July 12 according to an Alinta spokesperson.

International manufacturer Vestas supplied the turbines. Decmil is completing balance of plant, and civil works for the turbine foundations. The first 34 of the 51 4.2MW Vestas turbines have been installed.

Now the biggest wind farm in Western Australia, the project’s earthworks were worth $10 million. Earthworks were carried out by 45 Vernice employees, and 12 employees of other contractors.

The Yandin Wind Farm will not only be the biggest in the state, it will also be one of the most efficient in the country, delivering an average capacity factor of 50 percent. Alinta CEO Jeff Dimery told RenewEconomy its cost will be well below $50/MWh.

Steps

- Site clearing

- Substation pads laid for site offices, laydown areas, batch plant, and the substation

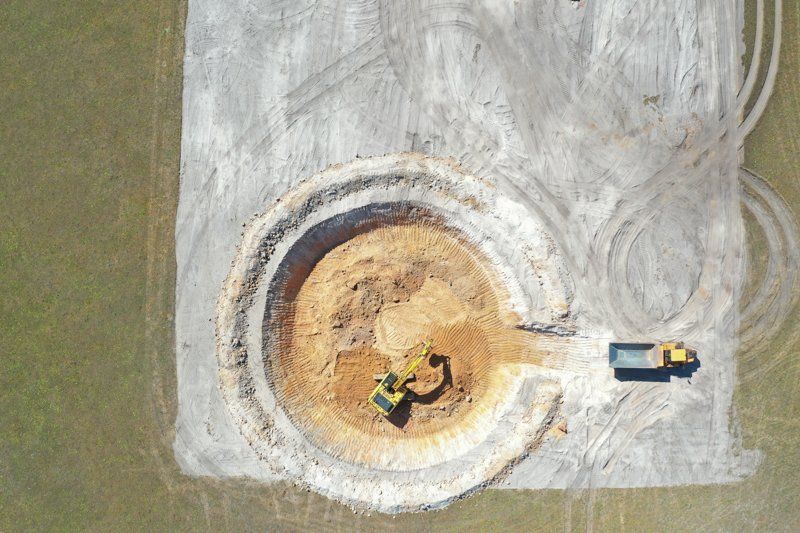

- 51 holes were dug in preparation for concrete foundation

- Once the foundation was set, the holes were backfilled with compaction testing using on-site sand and finished with gravel

- The pad was completed with gravel, compacted and tested at regular intervals

- Multiple pads were built to client specifications, including four temporary pads. Prior to project completion the temporary pads were destroyed and the land rehabilitated

The project covered numerous farms, with some turbine sites a 25min drive from the site offices. All access roads were created by Vernice.

120+ plant and machines used, including:

- 6X 5T-45T Excavators

- 3X Tipper Trucks

- 4X 966-972K Loaders

- 4X D7-D10 Dozers

- 3X Screening and Crushing plant

- 5X Rollers – smooth and padfoots

- 6X Graders

- 5X Articulated dump trucks 30-40T

- 3X Bobcats/Posi tracks

- 5X Semi-Trucks

- 5X Water carts

On-site materials were used where possible. Most materials were sourced from the Vernice gravel quarry.